Assistance System with Cascaded Pick-to-light Modules

KEB Automation optimized four workstations with an assistance system for manual order picking – intuitively guided using a ready-to-connect pick-to-light solution from Turck

In order to increase quality and efficiency with manual order picking tasks, KEB Automation tested a light-controlled assistance system on a packaging workstation. Turck provided the drive and control technology supplier with a pick-to-light solution based on the PTL110 series from its optical sensor partner Banner Engineering. The ready to connect complete package consisting of power supply, connection cables and bus-compatible PTL modules, such as lights, touch buttons or sensors impressed with its easy installation and wireless communication at selected points. At its headquarters in Barntrup, KEB is now already using the system at four packaging stations. The assembly area is the next plant section to also be optimized.

Bus-capable system instead of cable bunches

Thanks to their in-house expertise, KEB programmed a computer-supported user interface for touch monitors and then looked for the right pick-to-light solution with illuminated touch buttons or sensors. First results: “We definitely wanted to use bus-compatible components to reduce the installation effort at workstations with many compartments. Otherwise we would have had real bunches of cables on the shelves,” explains Phillip Hannesen, project engineer in electronics manufacturing at KEB. The market launch of the PTL110 series from Turck's optoelectronics partner Banner Engineering therefore came exactly at the right time – cascadable individual devices with a multifunctional indication, optional touch button, optical sensor and alphanumeric display. The modules communicate with each other via a Modbus-compatible protocol.

Complete package, ready-to-connect

Turck developed a ready-to-connect complete package for the easy onsite integration of the PTL devices, supplied by compact IP67 switched-mode power supply units and connected at both ends by pre-assembled cables plus a plug connector and Y splitter for feeding in the power supply at specific locations. An RS485-USB converter provides the connection to the computer. The new technical possibilities enabled KEB to constantly further develop the assistance system and the company's employees were also included in the development process from the start.

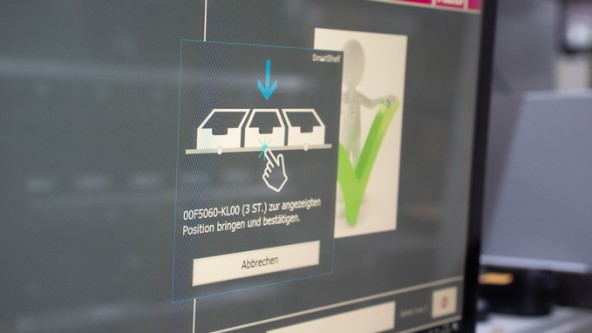

Acknowledgement by touch or optical sensor

Employees start an operation by scanning in a device serial number. The associated SAP work plan appears automatically on the screens, and a type label is likewise printed automatically and the material list called. While the monitors show illustrated instructions, a PTL110 module indicates the route to the corresponding removal point. In this case, it lights up in green with a momentary yellow flashing as soon as the pick is acknowledged via the capacitive touch button. Different processes take place in the loading zone, where pallets are placed on low stands and the PTL devices are not therefore mounted at head height. “We got the idea from the fact that the tailgates of several cars can be opened with a foot movement,” Hannesen recalls. KEB engineers therefore chose PTL modules with contactless detection for the collection points. Employees now carefully put down the packages with both hands and just have to place a foot underneath the optical sensor as an acknowledgement.

Wireless communication for remote areas

The pilot project involved crossing a forklift truck route between a core work zone and another location for goods ready for shipment. Instead of the labor-intensive cabling of the PTL modules over several meters, the East Westphalian specialists used a wireless connection with Banner's DX80 wireless system. Transmitter and receiver were installed within 30 minutes. “Plug and play” was the answer here, Hannesen explained. The wireless solution has already made an impression with KEB colleagues in the USA, who tested a mobile order picking station with 60 pick-to-light modules. Wireless communication would also be considered in future for combining an assistance system and intralogistic factory vehicles.

- Technologies

-turck-image.jpg)

-turck-thumbnail.jpg)