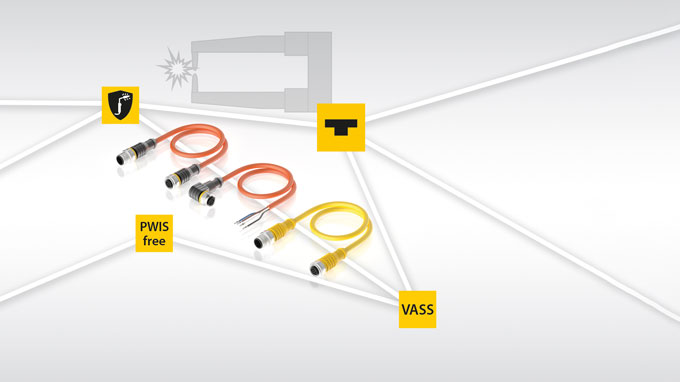

TXO and TXY cables: Flame-retardant, suitable for drag chain use and highly resistant to welding sparks

Welding Spark Resistant Connection Technology

The TXO3701 and TXY3713 series cables meet the most rigorous requirements of the automobile manufacturers for use in welding applications

Turck has increased the welding resistance of its TXO and TXY connector series. The cables thus also meet the latest requirements of the Volkswagen Group (VASS) for use in welding applications. The thickness of the cable jacket in particular was increased in order to achieve even greater resistance to welding sparks. The cables are also suitable for drag chain use and are highly flame resistant. They meet the requirements of both the North American UL FT2 standard as well as IEC 60332-1 and IEC 60332-2-2.

Your Benefits

- High process safety for welding applications

- Fast commissioning thanks to use of quick connectors

- Suitable for international use due to the wide acceptance of the VASS standard

Angled or straight cables – with or without LED

Turck offers the PUR cables as 4 or 5-pin variants with straight or angled connectors, both with or without LEDs. The user can choose between standard cable lengths for connection or extension cables with M12 connectors. The cables are available in orange or yellow as standard. Special lengths, custom jacket colors or cables with M8 connectors can also be implemented on request.

INDUSTRIES

- Automobile manufacturers

- Tier1 and Tier2 suppliers

- Machine building for welding applications

KEY FUNCTIONS

- Meets the requirements of the Volkswagen Group – VASS

- LED switching state indication (optional)

- AIDA compliant

- Flame-retardant

- UL and UKCA approval as well as CE

RELATED CONTENT

PRODUCT DATA

Learn more about the TXO3701 and TXY3713 Series

Approvals, data sheets, technical specifications, instructions, certificates, CAD data and more